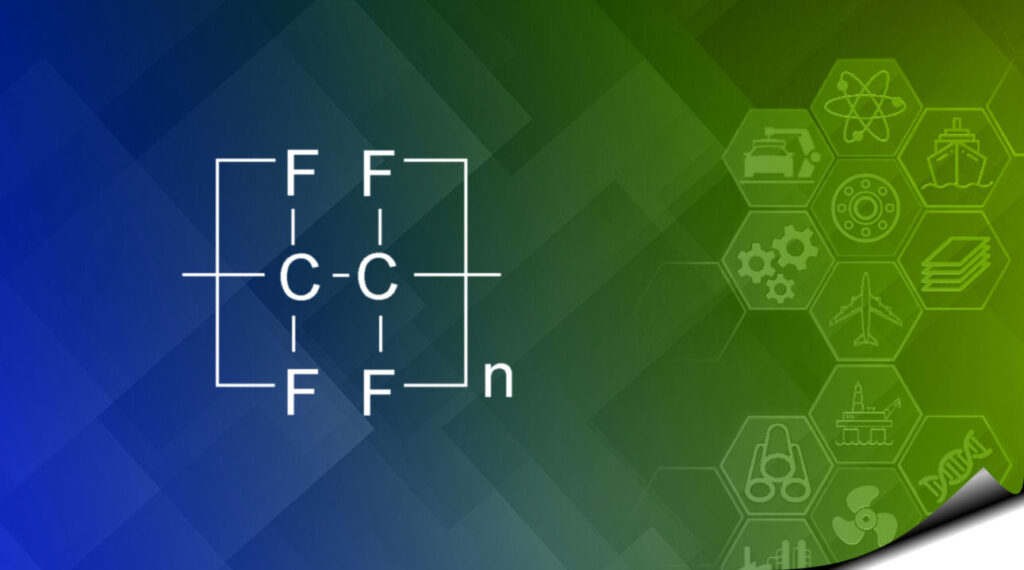

PTFE

- Virgin or modified grades for enhanced properties

- Low friction

- Non-stick (self lubricating)

- Low flammability

- High chemical resistance

- Highly flexible

- Typical max temp capability 260 deg C

Polytetrafluoroethylene (PTFE)

PTFE is a thermoplastic polymer, which is a white solid at room temperature, with a density of about 2200kg/m3. According to research, its melting point is 600K (327°C; 620°F). It maintains high strength, toughness and self-lubrication at low temperatures down to 5K (−268.15°C; −450.67°F), and good flexibility at temperatures above 194K (−79°C; −110°F). PTFE gains its properties from the aggregate effect of carbon-fluorine bonds, as do all fluorocarbons. The only chemicals known to affect these carbon-fluorine bonds are highly reactive metals like the alkali metals, and at higher temperatures also such metals as aluminium and magnesium, and fluorinating agents such as xenon difluoride and cobalt fluoride. At temperatures above 650–700°C (1,200–1,290°F) PTFE undergoes depolymerization.

The coefficient of friction of plastics is usually measured against polished steel. PTFE’s coefficient of friction is 0.05 to 0.10, which is the third-lowest of any known solid material (BAM being the first, with a coefficient of friction of 0.02; diamond-like carbon being second-lowest at 0.05). PTFE’s resistance to van der Waals forces means that it is the only known surface to which a gecko cannot stick. In fact, PTFE can be used to prevent insects from climbing up surfaces painted with the material. PTFE is so slippery that insects cannot get a grip and tend to fall off. For example, PTFE is used to prevent ants from climbing out of formicaria.

Because of its chemical inertness, PTFE cannot be cross-linked like an elastomer. Therefore, it has no “memory” and is subject to creep. Because of its superior chemical and thermal properties, PTFE is often used as a gasket material within industries that require resistance to aggressive chemicals such as pharmaceuticals or chemical processing. However, because of the propensity to creep, the long-term performance of such seals is worse than for elastomers that exhibit zero, or near-zero, levels of creep. In critical applications, Belleville washers are often used to apply continuous force to PTFE gaskets, thereby ensuring a minimal loss of performance over the lifetime of the gasket.

"Excellence afforded"

Ultra high performance polymers – delivered globally