PEEK

- Outstanding wear characteristics

- Excellent creep resistance

- High temperature capability

- Superb strength to weight ratio

- Radiation and chemical resistance

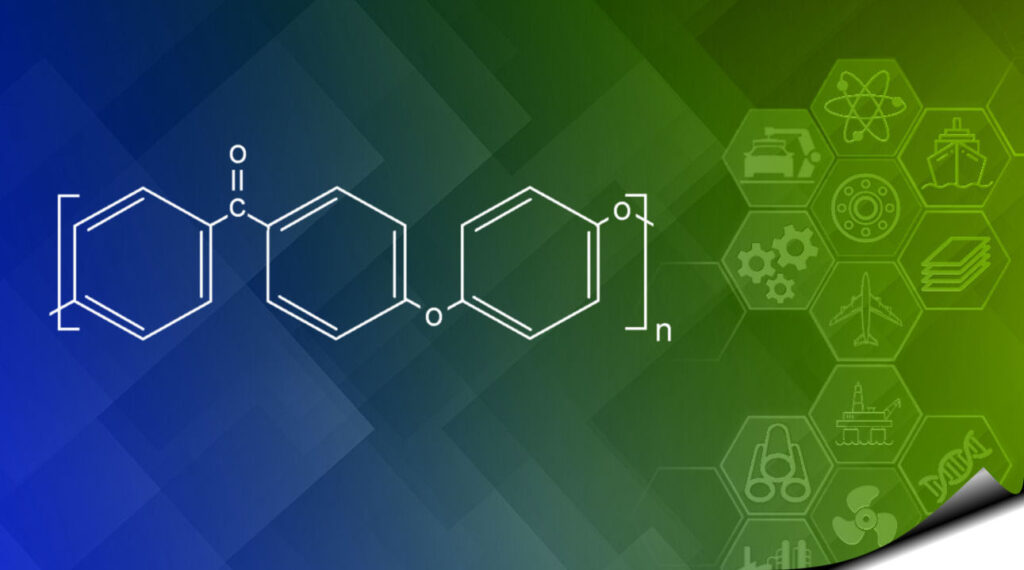

PolyEtherEther Ketone (PEEK)

PEEK is a semi-crystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures. The processing conditions used to mould PEEK can influence the crystallinity and hence the mechanical properties. Its Young’s modulus is 3.6GPa and its tensile strength is 90 to 100MPa. PEEK has a glass transition temperature of around 143°C (289°F) and melts around 343°C (662°F). Some grades have a useful operating temperature of up to 250°C (482°F). The thermal conductivity increases nearly linearly with temperature between room temperature and solidus temperature. It is highly resistant to thermal degradation, as well as to attack by both organic and aqueous environments. It is attacked by halogens and strong Brønsted and Lewis acids, as well as some halogenated compounds and aliphatic hydrocarbons at high temperatures. It is soluble in concentrated sulphuric acid at room temperature, although dissolution can take a very long time unless the polymer is in a form with a high surface-area-to-volume ratio, such as a fine powder or thin film. It has high resistance to biodegradation. Because of its robustness, PEEK is used to fabricate items used in demanding applications, including bearings, piston parts, pumps, High-performance liquid chromatography columns, compressor plate valves, and electrical cable insulation. It is one of the few plastics compatible with ultra-high vacuum applications, which makes it suitable for aerospace, automotive, teletronic, and chemical industries. PEEK is considered an advanced biomaterial used in medical implants, e.g., use with a high-resolution magnetic resonance imaging (MRI), for creating a partial replacement skull in neurosurgical applications.

PEEK is finding increased use in spinal fusion devices and reinforcing rods. It offers optimal bone growth and is radio-lucent, but it is hydrophobic causing it to not fully fuse with bone. PEEK seals and manifolds are commonly used in fluid applications. PEEK also performs well in applications where continuous high temperatures (up to 500°F/260°C) are common. Because of this and its low thermal conductivity, it is also used in FFF printing to thermally separate the hot end from the cold end.

"Excellence afforded"

Ultra high performance polymers – delivered globally