ECTFE

- Excellent chemical resistance

- Low coefficient of expansion

- Low permeability

- Excellent thermal stability

- High mechanical strength

- Outstanding machining properties

- Compatibility with high purity systems

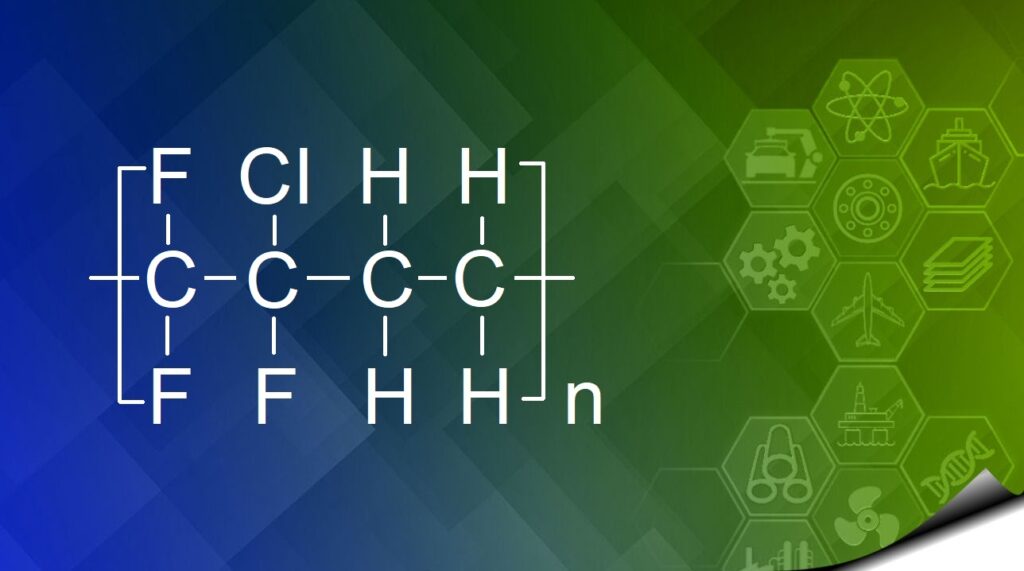

EthyleneChloroTriFluoroEthylene – ECTFE

Due to its chemical structure, ECTFE offers a unique combination of properties which are further enhanced and quality assured using specialist processing methods for the most demanding applications and product consistency.

Highly resistant to acids and oxidizing agents, the material offers the benefit of a lower coefficient of expansion than most other fluoropolymers, giving dimensional stability over a wide temperature range.

These properties are especially important in industries such as chemical processing where its high crystallinity and fluorine content make it resistant to most industrial chemicals.

Low permeability provides significant advantages where fugitive emissions are a consideration, making it an ideal material for use in the oil & gas industry whilst its high chemical purity makes the it an excellent choice in applications where ultra pure conditions are a critical requirement such as semiconductor, biotech and the pharmaceutical industry.

Extruded up to 3m in length from 12mm diameter up to 150mm diameter, the material is specially post processed to enhance its properties making it ideal for machining precision components.

Typical components made from extruded ECTFE rod

- Custom fittings and adaptors

- Precision machined sealing elements

- Machined components used in dispensing and dosing equipment

- Pump impellers

- Chemical injection system components

- Precision components for semiconductor wafer handling equipment

- High precision nozzles in semiconductor cleaning equipment

- Components for mixers and centrifuges in biotech lab equipment

"Excellence afforded"

Ultra high performance polymers – delivered globally