PCTFE (Kel-F®)

- Wide temperature capability (-260 to +150 deg C)

- Low permeability

- Harder than PTFE, greater wear resistance

- Excellent chemical and radiation resistance

- Superior cold flow characteristics

NEWS UPDATE

Availability and supply management

Due to international resin shortages, availability of this product continues to be limited, however, as a result of our close industry ties and key stakeholder relationships, we have been able to continue meeting most requirements of existing customers and have reserved capacity for future needs as part of our management of this material demand.

Please contact us for urgent requirements of this material.

Material grades, sizes & formats

- All products utilise resin from Daikin Industries with availability in M300H and M400H grades.

- Extruded rod 6mm to 70mm diameter, maximum length 3m

- Moulded tubes 40mm to 900mm diameter with extensive tooling combinations for efficient material utilisation

- Moulded sheets 290mm x 290mm, 290mm x 540mm & 540mm x 540mm – Thickness: 5mm to 40mm

- Available precision ground

- Annealed or otherwise thermally treated to specific requirements

- Aerospace grade available

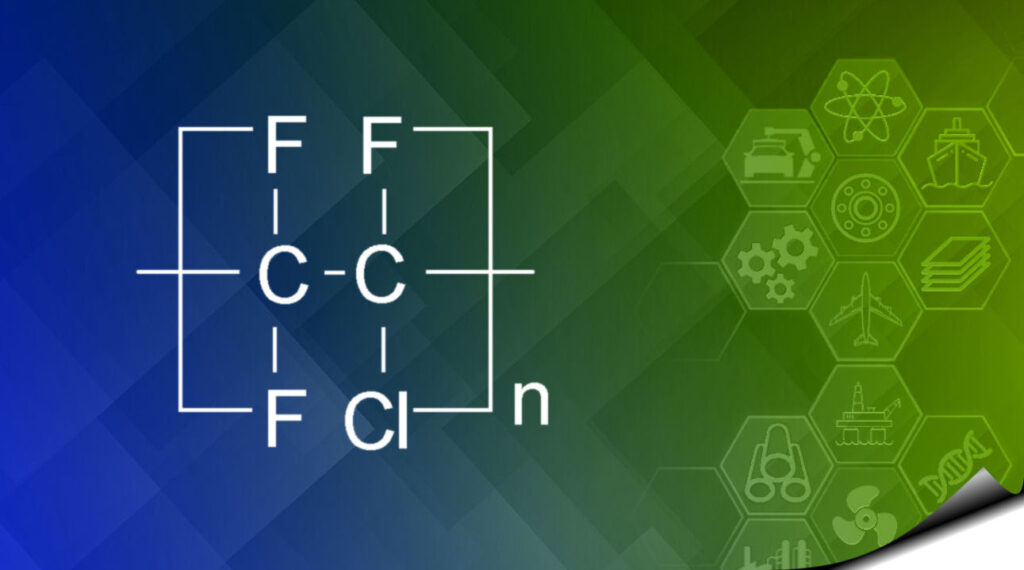

Polychlorotrifluoroethylene (PCTFE/PTFCE) Kel-F®

PCTFE was designed to work mainly in the cryogenics field of applications, this is due to its mechanical properties being retained at extremely low temperatures down to -270°C. With excellent chemical resistance, radiation resistance and flammability properties this makes it an ideal choice for cryogenic valves and when dimensional stability is essential.

PCTFE has high tensile strength and good thermal characteristics. It is non-flammable and the heat resistance is up to 180°C (short term). It has a low coefficient of thermal expansion. The glass transition temperature (Tg) is around 45°C.

PCTFE has one of the highest limiting oxygen index (LOI). It has good chemical resistance. It also exhibits properties like zero moisture absorption and non-wetting.

The presence of a chlorine atom, having greater atomic radius than that of fluorine, hinders the close packing possible in PTFE. This results in having a relatively lower melting point among fluoropolymers.

PCTFE is resistant to attack by most chemicals and oxidizing agents, a property exhibited due to the presence of high fluorine content. However, it swells slightly in halocarbon compounds, ethers, esters and aromatic compounds. PCTFE is resistant to oxidation because it does not have any hydrogen atoms.

PCTFE exhibits a permanent dipole moment due to the asymmetry of its repeating unit. This dipole moment is perpendicular to the carbon-chain axis.

History

PCTFE has been commercially available for over 70 years. Largely introduced by MW Kellog Company, it became most commonly used when manufactured by 3M under the trade name of Kel-F® (derived from Kellog and fluoropolymer) however, resin production was eventually taken over by Daikin Industries in 1995 who continue to produce several grades of Neoflon® resins to this day.

Technical differences PCTFE, Kel-F® and Neoflon® are often interchanged both in discussion and specification, however, it is important to be aware that there can be physical differences between these materials which may require consideration when specifying or ordering.

Kel-F® was a specific material processed to achieve particular physical properties which were unique to Kel-F®, however, that material is no longer available.

Grades of Neoflon® are available which can share some of the properties of Kel-F®, however, we always recommend checking and ideally testing that the grade of material you are purchasing meets your specific requirements.

Heat treatment Heat treatment of PCTFE is often misunderstood, poorly executed and sometimes ignored altogether.

In PCTFE, heat treatment isn’t only utilised to dimensionally stabilise the finished product but also has an impact on the crystalline structure which directly effects physical properties of the material. It must not be assumed that heat treatment is always desirable and the point of heat treatment of a component in the manufacturing cycle also needs to be considered.

To eliminate confusion during specification, at Engineered Polymers Limited, we offer unique material grades which denote specific physical properties, to help engineers specify the most appropriate grade for given applications and ensures correct grades are specified in the future.

Surface Grinding At Engineered Polymers Limited, we are able to provide precision grinding of our PCTFE extruded rod for those customers who need tightly controlled tolelerance on OD to increase efficiency, reduce cost and material wastage.

Machined Parts in PCTFE Engineered Polymers Limited is able to produce finished parts through turning, milling, drilling and post machining processing to produce high quality finished parts.

Our parts are mainly utilised in the medical equipment, oil & gas and industrial fields where the requirement is for a combination of the specific properties of our PCTFE grades together with the high levels of quality found in our finished parts.

Applications

Aerospace: PCTFE is used in aerospace applications for its exceptional low-temperature performance, moisture resistance, and electrical insulation properties. It can be found in critical components such as seals, gaskets, and insulators.

Pharmaceuticals: PCTFE’s chemical resistance and low moisture absorption make it suitable for use in pharmaceutical manufacturing, particularly in the production of seals, valves, and tubing for handling corrosive chemicals and maintaining product purity.

Chemical Processing: PCTFE is used in chemical processing equipment, such as valves, fittings, and pumps, where resistance to aggressive chemicals and solvents is essential.

Semiconductor Industry: PCTFE’s electrical insulating properties are valuable in the semiconductor industry, where it is used in the construction of high-purity gas delivery systems and as an insulating material for electronic components.

Cryogenics: PCTFE’s exceptional low-temperature performance makes it a preferred material for cryogenic applications, including seals, gaskets, and components in cryogenic storage and transfer systems.

Oil and Gas: PCTFE is employed in the oil and gas industry for its resistance to corrosive fluids and gases. It is used in valves, seals, and fittings in harsh environments, specifically low temperature applications such as LNG valves and associated equipment.

Scientific Instruments: PCTFE is used in analytical instruments, such as chromatography systems and spectroscopy equipment, where its chemical resistance and low moisture absorption are advantageous.

Electrical Insulation: Due to its electrical insulating properties and moisture resistance, PCTFE is used in electrical connectors, insulators, and wiring applications.

Medical Devices: In medical applications, PCTFE is utilised for its biocompatibility, chemical resistance, and low moisture absorption. It is used in components like seals and valves in medical devices.

Optics: PCTFE is used in optical applications, including lens mounts, windows, and optical components, thanks to its optical clarity, low refractive index, and resistance to moisture and chemicals.

"Excellence afforded"

Ultra high performance polymers – delivered globally